Planet Under Construction

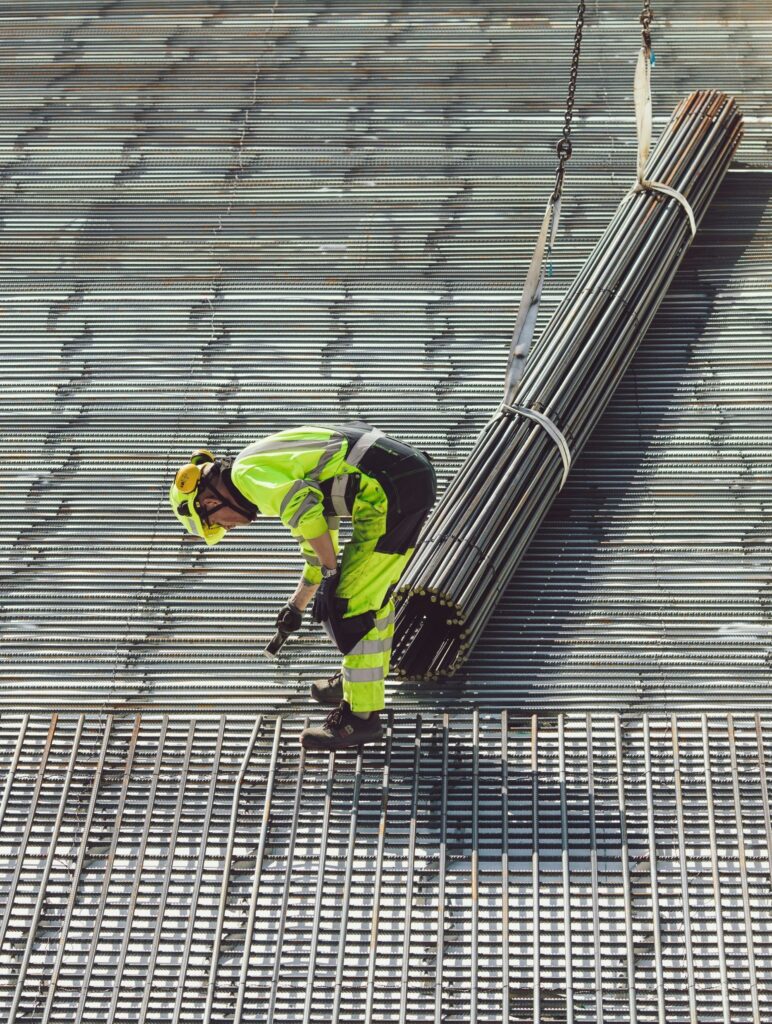

The urgent need to rethink how we build.

Europe is facing a pivotal moment in how it builds. From carbon emissions and energy use to construction waste, the building sector is a major contributor to Europe’s environmental footprint. It’s more crucial than ever to rethink the way we design and construct our buildings to keep valuable resources in circulation for as long as possible and reduce our impact on the planet.

Within the European Union, the construction industry accounts for almost 40% of total emissions and produces nearly a third of all waste. Despite growing awareness, the progress towards a circular economy in this sector remains limited.

In 2021, the EU’s construction sector had an estimated material circularity rate of just 11.7%, highlighting how much work still needs to be done to move towards more sustainable, resource-efficient building practices.

The built environment generates high emissions because it depends heavily on finite resources like sand, gravel, and metals, consuming natural materials at a pace the planet can’t sustain. These materials are dug up, processed, and shaped into the concrete, bricks, steel beams, and glass used to build our cities and towns. The problem is, many of these resources are limited and their extraction often harms the environment by damaging landscapes, destroying ecosystems, and producing harmful greenhouse gases.

On top of this, vast amounts of waste are produced throughout the lifecycle of buildings. Much of this ends up in landfills or is incinerated, contributing to environmental pollution and the depletion of natural resources. Out of the huge amount of waste generated, only about 40% gets reused or recycled. And when it is, it’s typically downcycled into lower-grade materials, rarely making it back into new building projects.

As construction continues to grow, this increasing pressure on the planet’s resources and insurmountable waste only highlights the need to find smarter, more sustainable ways to use and reuse materials.

Recognising this, in March 2020, the European Commission introduced a new Circular Economy Action Plan as a key part of the ambitious European Green Deal – Europe’s strategy for sustainable growth. The essential move towards a circular economy is expected to ease the demand on natural resources, create new jobs, and support long-term economic growth, all of which are required to reach the EU’s goal of becoming climate-neutral by 2050.

The plan outlines steps for every stage of a product’s journey, from design to disposal. It aims to make products more sustainable, promote circular business models, inspire responsible consumption, and reduce waste.

At its core, it involves designing, building, using, and eventually repurposing structures and materials in a way that conserves resources, limits pollution, and protects ecosystems. For buildings specifically, circularity is about maximising resource efficiency and minimising waste throughout the entire lifecycle, from initial design and construction to renovation and eventual deconstruction.

With raw material costs climbing and natural resources becoming increasingly scarce, the construction industry is turning to waste materials as a practical alternative. When properly treated and processed, these recycled materials can perform just as well as traditional options and meet the necessary design and safety standards.

What if Europe rethought how it builds?

The EU is driving investment into innovative, sustainable solutions that can pave the way for a revolutionary shift in how we use materials in the construction sector.

One ambitious, forward-thinking initiative in the field is ICARUS, a project that transforms industrial waste into high-quality secondary raw materials (SRMs). With 18 beneficiaries from Spain, Portugal, Belgium, Italy, Germany, France, and the Netherlands, ICARUS, funded by the EU’s Horizon Europe programme and spearheaded by ACCIONA’s Construction business, aims to make Europe the first digitally led climate-neutral economy through the transformation of its mobility, energy, construction, and production systems.

It aims to close the loop in construction, significantly cut down on waste, reduce environmental impact, and ensure materials meet the same standards as virgin resources. ICARUS created an innovative opportunity to give waste products a new life and keep them in circulation for longer.

Through new recycling and upcycling methods, the initiative is showing that it is possible to build sustainably without compromising on performance. Its work is not only changing the construction industry but also helping create a future where we can use resources more efficiently whilst still doing good for the environment.

This shift isn’t just necessary, it’s inevitable.

To tackle the carbon footprint of this resource-intensive industry, this EU-funded project has three key demonstration case studies that are excelling across Europe.

Turning lithium residue into strong, sustainable materials

Leftover waste materials, such as a by-product called lithium aluminosilicate residue (LAR), can be reused to make useful things such as cement, concrete, road base, backfill, and ceramics. This project is working on better ways to treat and strengthen LAR so it can be used safely and reliably in construction, thus reducing the need for new raw materials and giving industrial waste a second life in sustainable building.

Recovering cellulose from everyday waste

Waste materials like used diapers and wastewater might seem useless, but they contain valuable fibres that can be recovered and reused. These fibres are cleaned, processed, and reused in construction materials and other bio-based products. By targeting both hygiene product waste and wastewater sludge, ICARUS is helping reduce landfill use and emissions. AI-powered systems help make the process efficient and ensures the recycled materials are safe and of high quality.

Making use of steel slag for greener building products

Businesses in construction and manufacturing have a big opportunity to turn leftover waste from steelmaking, called slag, into something useful. This waste can be processed into precipitated calcium carbonate (PCC), which is used in things like building materials, ceramics, and even to make more steel. The process also helps by capturing carbon dioxide and reducing the need to dig up new limestone. The initiative is improving this method to make high-quality PCC and looking for other ways to reuse slag, showing how industrial waste can be part of climate-friendly, circular solutions.

So, the good news for the construction industry is that change is already underway.

Projects like ICARUS are bringing circularity out of the conceptual realm and into practical, measurable progress – one industrial byproduct at a time. While circular economy concepts often shine in theory, real-world application is where their true potential is tested.

We must continue to think outside the box when it comes to resources. Embracing a circular economy in construction isn’t just good for the planet, it’s essential for long-term economic resilience, resource security, and healthier, more sustainable cities across Europe.

Continuing this necessary shift will allow Europe to position itself as a leader in the circular built environment globally and give itself the power to reshape our cities, protect natural resources, and secure a greener, more resilient future for generations to come.