Transformative Digitalization in the Food Industry

Harnessing the power of digital twins, AI, and blockchain to revolutionize the food supply chain.

Digitalization is poised to play a significant role in transforming the food industry. Drawing parallels from a 1995 tire advertisement which famously stated, “Power is nothing without control,” the vast potential of digital technologies can only be realized through their practical application in specific, real-world contexts.

Digital transformation is not just a theoretical concept. It is a necessary evolution for improving accuracy, efficiency, and sustainability in food production. This transformation is illustrated through our work at BBTWINS, an EU-funded partnership between industry and research harnessing the power of machine learning and deep learning and using artificial intelligence (AI) algorithms analyze vast datasets to predict crop yields, optimize resource allocation, and reduce waste.

We combine AI and blockchain-based traceability in this single platform to address concrete challenges and enhance process efficiency in both pork and peach production.

The core of the project is the digital twin technology, virtual representations of physical objects or systems that are used for simulation, analysis, and control. They are created by linking real-world data from sensors on the physical entity to a digital model, allowing for real-time monitoring and optimization. At BBTWINS, we combine AI and blockchain-based traceability in this single platform to address concrete challenges and enhance process efficiency in both pork and peach production using the power of digital innovation for a more sustainable agri-food sector.

From Pigs to Peaches

In the pork industry, raising animals to a given optimal weight is key. Monitoring growth also helps identify sick animals and the effect of their diet. With traditional methods like scales, monitoring is both time-consuming and prone to error.

Imagine weighing a 120 kg pig. One must guide the animal out of its cage and then onto the scale for measurements before sending it back. Let’s assume the whole process takes three minutes. Now think of a medium-size farm of 200,000 heads of livestock. It would take 10,000 hours to weigh tall the animals just once in their life – more than a full year of measuring around the clock. If weights are to be monitored it would make sense to take measurements every week – it’s unaffordable.

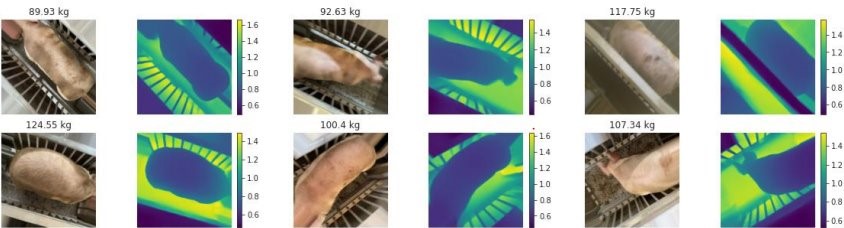

The industry relies today on trained workers who visually inspect animals and mark those that appear to have reached the desired size. An extremely inaccurate method, to say the least. In BBTWINS, by integrating AI with image processing technologies, cameras equipped with AI algorithms continuously capture and analyze images of the pigs.

This system not only predicts the weight of each pig with remarkable accuracy but also tracks their growth over time, reducing the variability associated with manual assessments. Such technology ensures that we maintain high-quality standards while significantly reducing the labor and time traditionally required for such tasks.

Such technology ensures that we maintain high-quality standards while significantly reducing the labor and time traditionally required for such tasks.

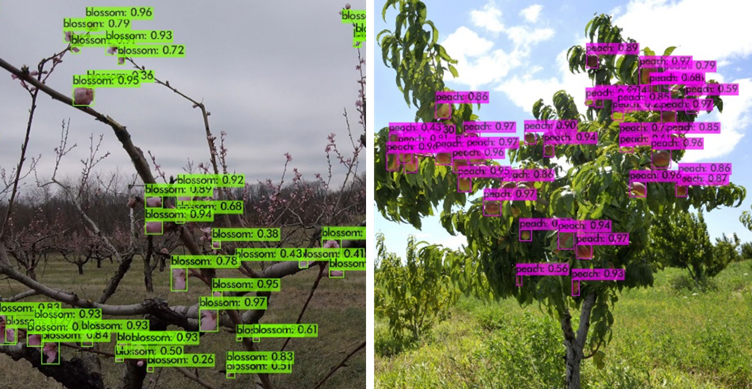

For fruit production, specifically peaches and nectarines, we face different challenges, primarily in optimizing fruit yield per tree. Picture a peach orchard blooming in spring, boasting white flowers worthy of an impressionist painting. As pretty as this may be, the farmer’s attention is likely focused on more practical matters – too many flowers mean too many small peaches, and there are only so many nutrients a tree can convert into fruit. But too few flowers may result in peach sizes over the desired caliber that are too expensive for the average consumer.

One may think that farming is pretty much just sitting and waiting, and that nature will just give you what you want, but it’s far more complicated.

Once again, the year’s harvest depends on the visual inspection of a trained eye. By mounting cameras on tractors that traverse our orchards, BBTWINS collects images that are automatically processed to assess flower and fruit count. These images, analyzed using sophisticated algorithms, help us make informed decisions about how many fruits to thin out to achieve the optimal size and quality at harvest.

This method not only enhances our yield quality but also supports sustainable farming practices by enabling precise resource management.

Blockchain Guarantees

Another cornerstone of our digital strategy is the use of blockchain technology to ensure robust traceability across our supply chains. In an industry where transparency increasingly influences consumer trust, labels are simply not enough. Nowadays, labels are crowded on the containers ensuring the origins of the produce or how socially and environmentally responsible the production process was; however, the European Commission has concluded that more than half of the green claims give vague information, and more than 40% have no supporting evidence.

In an industry where transparency increasingly influences consumer trust, labels are simply not enough.

What if we could rely on proven facts, rather than trust? Blockchain offers an unalterable record of every transaction and process. You can be sure of a produce origin and fully trust in the production chain.

This technology not only facilitates internal management and compliance with industry safety standards but also enhances consumer confidence in products by providing a clear, traceable path from farm-to-table. BBTWINS records data along the entire pork and peach production chain, expecting to provide QR codes for consumers to scan and know all about what they consume.

And the technology can also be used for other agricultural production and livestock, meaning that BBTWINS has the potential for revolutionizing the entire agrifood sector.

Some Challenges to Address

However, the integration of these technologies is not without challenges. It requires significant investment in both technology and training, as well as a thoughtful approach to data privacy and workforce adaptation. For instance, the integration of AI and blockchain technologies may pose challenges in complying with data privacy regulations like the EU’s General Data Protection Regulation (GDPR), data storage can create vulnerabilities if not implemented securely, and maintaining control over data governance and ensuring that data is used ethically and in compliance with regulations can be complex.

Furthermore, as we automate more processes, we must also consider the social implications, particularly the impact on employment within the industry and the necessary skills transition for our workforce. There are several EU initiatives to address the needs of the workforce, particularly on building data literacy and also developing AI literacy so workers can understand their new role in the workplace and properly use such technologies to their own benefit.

As we look towards the future, the role of digital twins and related technologies in agriculture will continue to expand. These tools not only offer a way to optimize production but also serve as a crucial component in making the food supply chain more sustainable, resilient, and responsive to global needs. By embracing these innovations, we not only transform our business operations, but we also become part of a united effort to redefine the entire industry for the better.