Sustainable Fuels for Aviation

Researchers race to develop and certify sustainable aviation fuels made of biowaste to meet EU targets

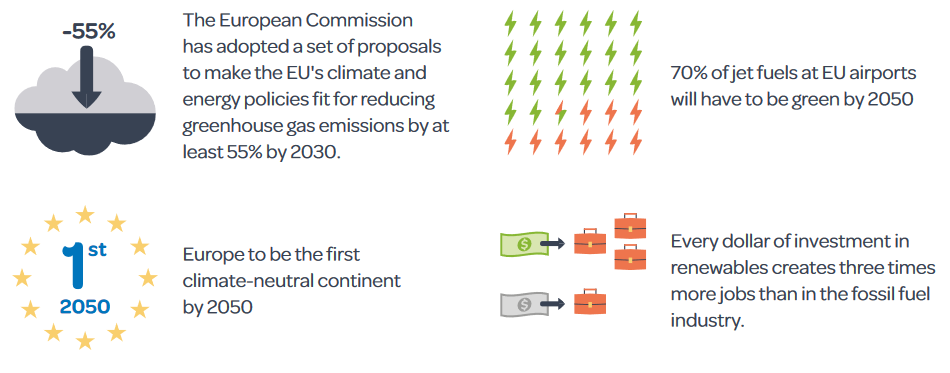

The aviation transport is one of the most carbon-intensive sectors, accounting for 14.4% of the European Union’s total transport emissions. To reduce the sector’s emissions and support the EU’s transition to being climate-neutral by 2050, the Fit for 55 package has proposed a set of measures, including the increased use of greener aviation fuels. So far, efforts have been carried out to reduce CO₂ emissions in the transport sector, including the use of electric vehicles as a potential solution. However, replacing fossil kerosene on large passenger transport and long-haul flights, remains a challenge. Thus, the aviation sector is still in need of greater innovation and higher deployment of sustainable fuel alternatives.

The Fit for 55 package aims to increase the use of sustainable aviation fuels (SAF) on aviation sector and sets more ambitious targets to ensure relevant pricing of aviation emissions. In particular, the RefuelEU aviation regulation will require aviation fuel suppliers to ensure that of the fuel available to EU airports in 2025, a minimum of 2% must be SAF, increasing to 70% of all fuels in 2050. Part of this SAF will be supplied with green hydrogen and the production of advanced biofuels, such as forestry waste and agricultural residues, which are more sustainable than crop-based biofuels.

Globally, which Sustainable Aviation Fuels (SAF) are currently available?

As of 2022, there were seven certified SAF production routes and more than 10 routes are expected to become available, or certified, during the upcoming years. Circular Fuels’ solar-driven fast pyrolysis oil production and its solar H₂ upgrading is hopefully one of them. In 2022, SAF covered only 0.2% of the global need for kerosine, so there is a significant need for further development to reach the emission targets set for the aviation sector.

How circular can fuel production and consumption really be? Which SAF has the most circular potential?

At Circular Fuels, we are focusing only on waste-based materials without creating a case that the side/waste-product starts to increase the need for primary material. This can easily be the case with, for example, virgin forest or woody materials. Of course, when burned in the jet engine, the loop ends. Going forward, we should develop methods that capture CO₂ from air and seawater, and that return the used carbon as a raw material.

The most important solution to reduce emissions is, of course, to reduce all our consumption, including flying.

Considering the many SAF and more sustainable aircraft technologies being explored, what should EU policymakers prioritize in innovation and development?

When it comes to innovation and development, there is a need for establishing a shared framework regarding what exactly encompasses ‘sustainability’ while also defining what comprises a sustainable biomass source. Perhaps we need to set incentives and funding support mechanisms to upscale renewable energy generation and production processes of green hydrogen. To make SAF more feasible, there is a need to implement support mechanisms for concentrated solar heat systems, and removing harmful fossil subsidies (both direct and indirect).

How can the production of SAF ensure that produced fuels do not lead to adverse effects on land and climate?

We need to only use waste-based materials and ensure that we are not increasing the production of the primary product – which would generate more waste. If, and as, sustainable waste-based materials are probably not sufficient to cover the overall need for replacing all fossil consumption, we need to also work hard to further develop the e-kerosine pathway, producing SAF from sustainable green hydrogen and captured CO₂. The source of CO₂ can be biogenic, and the sustainability of the source must be secured. We need to develop Direct Air Capture of CO₂ methods, and study Direct Ocean Capture technologies. The most important solution to reduce emissions is, of course, to reduce all our consumption, including flying.

How will the Circular Fuels project create more sustainable fuels, considering that the produced SAF are limited?

In the future, we will need to have all possible processing pathways and waste-based raw materials in use. There is no single solution. Regarding the Circular Fuels project, we are developing a new solar fuels concept that maximizes the utilization of the raw material since it is not burned to run the processes but, rather, all energy is acquired from the sun. We also need to boost the implementation of the e-Kerosine pathway.

What is the most innovative aspect of the Circular Fuels project and what benefits can it bring to society and the environment?

The most innovative aspect of Circular Fuels is the utilization of solar energy, both as solar heat to run the thermal conversion processes and as solar PV power to produce solar green hydrogen via electrolysis. By doing this, Circular Fuels is avoiding the burning of raw materials.

How will the Circular Fuels project ensure that the feedstock used will not limit the needed use of debris for improving soil fertility and water saving through mulching?

The Circular Fuels project is focusing only on waste-based raw materials; such as demolition wood and different straws from agriculture. We are mapping and reporting the available volume of these in several EU countries. We will exclude straw streams that are needed and currently used for soil improvement – without creating a new need for them.

Circular Fuels is an EU project that aims to develop sustainable aviation fuels from agricultural waste and used demolition wood waste. Solar heat is used to first convert waste materials into bio-oil, which is then converted to high quality jet fuel by processing it with solar electrolysis-based green hydrogen.