Bringing Sustainability to the Oil and Gas Industry?

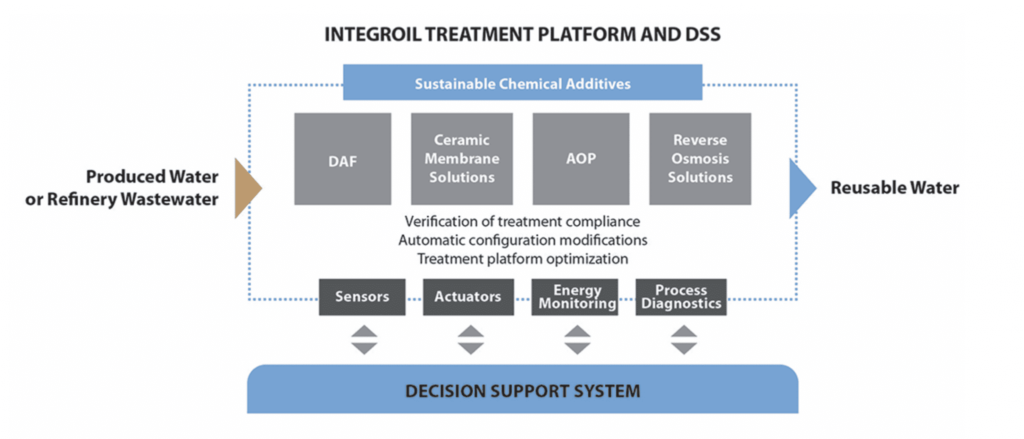

The INTEGROIL project seeks to develop and demonstrate an integrated solution for the treatment of water flows generated in the upstream and downstream activities of the oil and gas industry. The main feature of these waters is their extreme high variability, which makes them difficult to be treated with standard treatment options. The proposed solution involves a combination of innovative treatment technologies effectively operated and optimized through a novel Decision Support System (DSS). Thus, one of the main goals of the technology is to be able to reduce the industrial water demand by 50% by producing water of high enough quality to be reused.

What makes the INTEGROIL concept and technologies being deployed so sustainable?

The INTEGROIL concept and technologies provide three key improvements in terms of sustainability. In all three steps the Decision Support System (DSS plays a key role).

First, the technological scheme enables the production of fit-for-use reclaimed water. The DSS is capable of dynamically adjusting the treatment scheme needed to achieve the water quality targets based on the incoming water quality and the performance of each individual process. The DSS is flexible and robust enough to deal with highly variable water compositions.

Secondly, the technologies that integrate the solution can deal with complex waters in situ, enabling the removal of recalcitrant compounds in a reliable way, complementing each other. Most existing treatment schemes have troubles when dealing with such kind of compounds, thus limiting the safety reuse of complex water. In this case, the DSS provides advice about which individual technology should be activated and in which configuration to ensure the removal of recalcitrant compounds.

Finally, the DSS enables the optimization of each of the operative processes, leading to lower energy and chemical consumption. Because the DSS selects the optimal treatment scheme and actuates in the system activating and deactivating processes, it is not necessary to have a high degree of expertise in water treatment. This is an additional advantage that makes the deployment of INTEGROIL technology at large-scale easier.

Why is it important to develop an integrated water treatment solution from an economic, environmental and social perspective?

In advanced economies, as much as 45% of all water demand is generated by industry. On the other hand, several geographic regions are facing water scarcity problems. The INTEGROIL project aims at facilitating water reuse particularly in water intensive industrial sectors. INTEGROIL thus contributes to alleviating the pressure on water resources and reducing the dependence to fresh water sources.

To ensure INTEGROIL’s implementation, not only it should be advantageous in terms of sustainability, but also in economic terms. High costs are one of the main barriers that prevent new technologies from entering the market. The integrated solution should present competitive costs compared to the conventional technologies currently used, also enabling greater competitiveness of those industries adopting this approach.

The social perspective is important from a commercial two-fold perspective as well. First, the safety of reused water is always a hot topic, its use being controversial in certain applications even though the safety of reclaimed water is ensured if a proper treatment is implemented. Awareness-raising campaigns are included as part of INTEGROIL activities in order to improve the social perception of reused water. Secondly, water-intensive industrial sectors are very sensitive to public perception. These industries are making strong efforts to implement sustainable technologies that contribute to improving their commercial brand. INTEGROIL helps them to achieve these objectives.

It is very important to consider environment, economy and society when developing new products and services, but especially to achieve a greater commercial impact.

How will INTEGROIL’s Decision Support System add value to other industries?

Nowadays the DSS effectively manages five different technologies: a dissolved air flotation (DAF), a ceramic ultrafiltration (UF), a catalytic wet air oxidation (CWAO), an advanced oxidation process (AOP) and a reverse osmosis (RO). These technologies, along with the DSS, are being tested in a demonstrative pilot plant (1.5 m3/h nominal capacity) in two representative applications from the oil sector. One corresponds to the upstream scenario, illustrative of the oil extraction, and the other to a refinery, which corresponds to the downstream scenario. The demonstration activities related to the upstream scenario were completed in October 2018 and currently the demonstrative plant is being assessed in the downstream scenario, dealing with wastewater from a refinery continuously (24/7). As a result, a wide range of conditions will be assessed for over a year to demonstrate the reliability and applicability of the INTEGROIL solution. It is important to highlight that the size of each unitary process has been selected in such a way to ensure that the results can be scaled-up and thus, are representative for full-scale applications.

For each scenario, different water reuse applications have been defined, setting the quality needed in each case. Each of the five abovementioned technologies has been thoroughly characterized in technical and economic terms regarding operational limits, removal efficiency, energy and chemical consumption.

During operation, the DSS reads the measurements from online sensors, which provide information on the incoming water quality, the final use of the reclaimed water and the technical-economic assessment of each technology. Based on this information, the DSS defines the optimal treatment train that ensures the final water quality with minimal costs. This computation is conducted in a dynamic way, so that for example, if the influent water quality varies or the final use of the reclaimed water is modified, the DSS will re-calculate whereas it is more appropriate to modify the treatment scheme. If so, the control system will actuate on the valves the engines to activate and deactivate the required unitary processes, implementing the optimal treatment scheme. As a result, the reclamation process is adapted on real time to the specific needs, making an optimal use of resources.

The DSS is currently being assessed in the oil sector but it is expected to be applicable in other industries with complex highly variable water streams. In this case, other processes can be added to the DSS algorithm as well as additional sensors and associated parameters. Moreover, water quality targets can be added to the DSS, customizing it as needed.

As a result, the DSS will also turn into greater sustainability for those industries implementing it, because on one hand it will facilitate the reclamation and reuse of water streams, providing fit-for-use water, and on the other, it will enable the optimisation of processes, turning into lower energy and chemicals’ consumption.

What are the challenges to commercialize these technologies?

Market uptake of INTEGROIL technology will face two main challenges. The first is the composition of the oil and gas market, the primary application for INTEGROIL technology. This is a market dominated by a few, but very large players—each of them accounting for large market shares. Moreover, the financial and business model of the oil and gas industry differ from those commonly used in the water treatment sector. Secondly, and closely related to the previous barrier, it is the need to have demonstrated technologies. In the oil and gas market, nobody wants to be the first to test new technologies because main companies in the field shy away from potential liabilities and risks.

INTEGROIL identified these two challenges at the very beginning of the project, so appropriate activities to achieve them are ongoing. Specifically, INTEGROIL includes market preparation activities as well as long-term demonstration tests in real conditions, both in upstream and downstream scenarios and in the widest sense of the demonstration word: with sufficient testing time, reliable scale, treatment of real water in a continuous way. Finally, an Advisory Board with representatives of the oil and gas industries and other industrial sectors that share similar challenges in terms of complex water treatment is assessing the project partners from a commercial and technical point of view.

When do you expect this technology to be on the market?

Refinery demonstration activities of INTEGROIL are going to end in May 2019. At that moment, the INTEGROIL technology will have an equivalent Technology Readiness Level (TRL) of 7, which means that the system prototype has been demonstrated in operational environment.To have the system completed and qualified (TRL 8) final normalization, scale up and cost optimization tasks are required. Once finished (late 2019 – early 2020), the INTEGROIL technology will be ready to enter the market.