Organic, Biodegradable, Reusable: Transformative Products From Olive Stones

Toys that can become bowls, chairs that can grow plants, and exhibition stands that can shift for each new edition. These are only the first three lines of application for Re Olivar, the new bio-composite based on olive stones. Organic, biodegradable, reusable and highly fashionable, Re Olivar offers new possibilities for repurposing.

The basic mixture of ground olive stone with other natural ingredients can be formed into a wide variety of textures and appearances, depending on the amount and type of stone material used – granulate, powder or flour. The material can appear wood-like to transparent and is remarkably malleable. The biocomposite is available in different colors thanks to a dying process using only natural sources such as turmeric, avocado, indigo, and cochineal.

Products made from Re Olivar can be melted and reused again for the same or a different purpose with virtually no loss of material. “The customers can choose between discarding the final, biodegradable products or use their creativity to manufacture a new one from our material,” explains Silvana Catazine, co-developer of Re Olivar with Joseán Vilar.

In their creative studio, Naifactory in Barcelona, Catazine and Vilar have already set up three lines of Re Olivar products with high customization potential.

Toys with a future

Of products on the market, toys have one of the shortest life spans – 90% of which are made of plastic. As most toys outlast children’s interest in them, they are a large source of plastic pollution. In search of a more sustainable alternative, many parents are turning to natural materials, such as wood.

The granulate version of Re Olivar provides a similar look, texture and function – while being much lighter. And better yet, when tired of playing with the toy, the child can find another source of joy by transforming it into a new object.

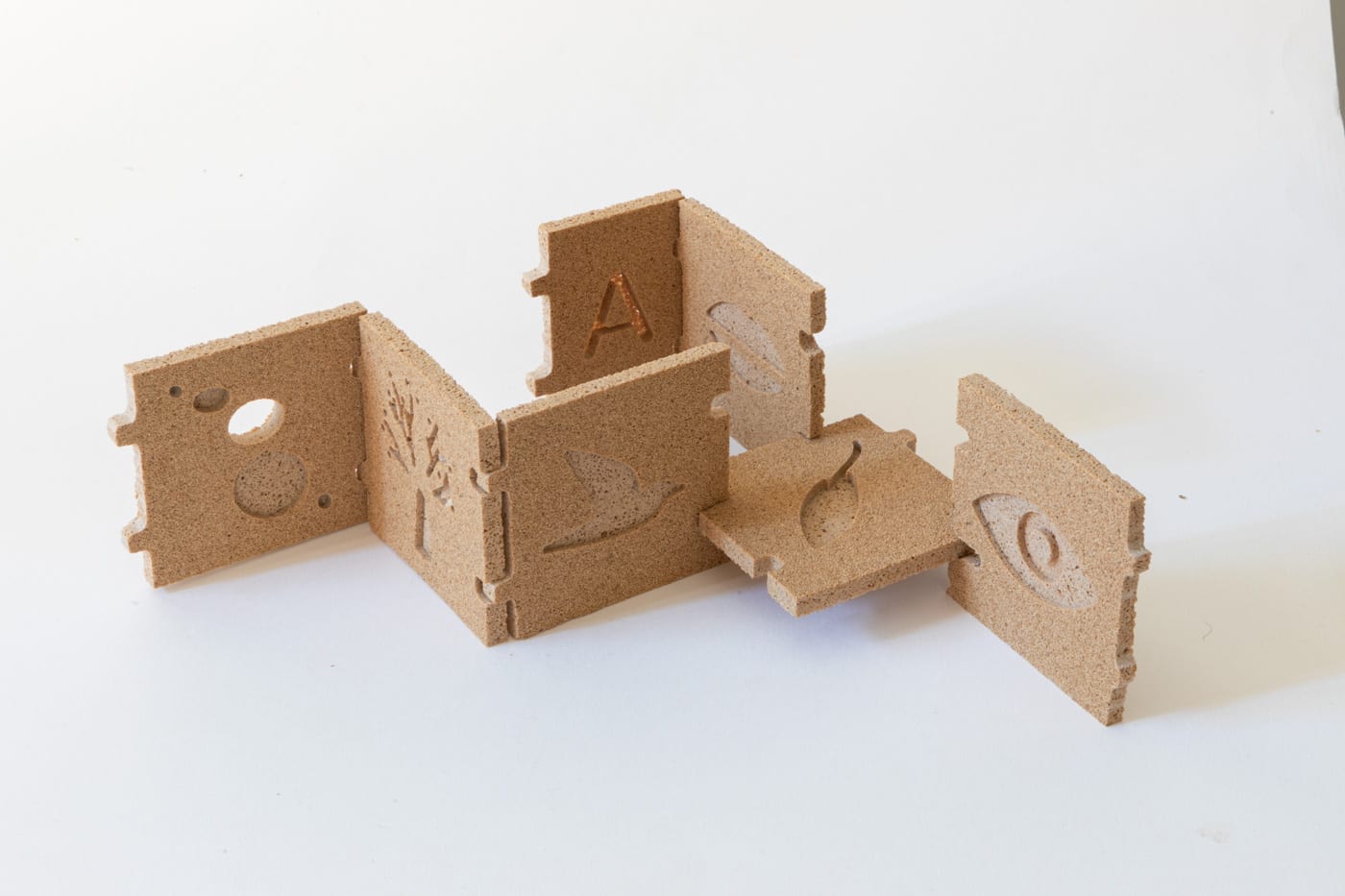

The first model being developed is a 3D puzzle that will include colored inserts made out of another version of the biocomposite material. Developed for a Barcelona-based toy and decor company, it will hit stores before the summer.

Living furniture

While researching the suitability of Re Olivar for decorations and small furniture, Catazine and Vilar designed a chair for children. With the vision to increase its sustainability even in its afterlife, they embedded it with seeds. When the child outgrows the chair, he or she can bury it outdoors and watch a plant sprout out of their former seat.

To incorporate the Sustainable Development Goals within their project’s approach, they are currently looking for foundations or enterprises with social inclusion programs as manufacturing partners.

Not-so ephemeral architecture

Every year 4.4 million companies display their products at fairs and trade shows.

The search for stands that meet sustainable criteria has become an increasing challenge, with wood and plastic panels still leading as the materials most often used. Re Olivar panels allow for a great versatility of shapes, textures and colors and can be reused time and again and their light weight makes them more transport-friendly than wood.

The Re Olivar panels will début on 14 May at the 21 Feira Ópera in São Paulo where they will reinforce the message for the summer edition of the international trade show: “There is no B planet.”

Work for progress

Focused on design for circular economy, the founders of Naifactory define Re Olivar as a project with several ongoing research fields. In their quest to foster locally-based products, they turned to olives as their proof-of-concept raw material because Spain leads the world production with a 21% share. The stones –which make up 15% of an olive weight– have been traditionally neglected as waste, and only recently found their way into the cosmetic and mainly the biofuel industries. Re Olivar bioplastics unfold a whole new realm of applications, which can be replicated with different local by-products in other parts of the world. That’s why the designers are already working with rice in the Valencia region or cassava peels in Brazil, while also testing new organic binders to add different qualities to the basic mixtures. The no-waste, circular journey has just begun.