Accelerating The Transition To The Circular Economy

How to accelerate the global paradigm shift need for going circular across all industries.

What if virgin, raw materials became completely inaccessible overnight? How would society continue? Would it collapse? Would it thrive?

Fortunately, this is just a hypothetical, but one we can benefit from. Suddenly we would look at every component, product, building, bridge and road with fresh eyes. What else can it be? What else can it do? What can we reuse? What can we repurpose? What can we recycle? What can we refurbish? What can we reinject into the manufacturing cycle for renewal before we tap into our very precious reserves? What new services or technologies would emerge?

We could fundamentally change the way we design, manufacture, build and deconstruct. We would activate the circular economy.

Cascading and Recapturing

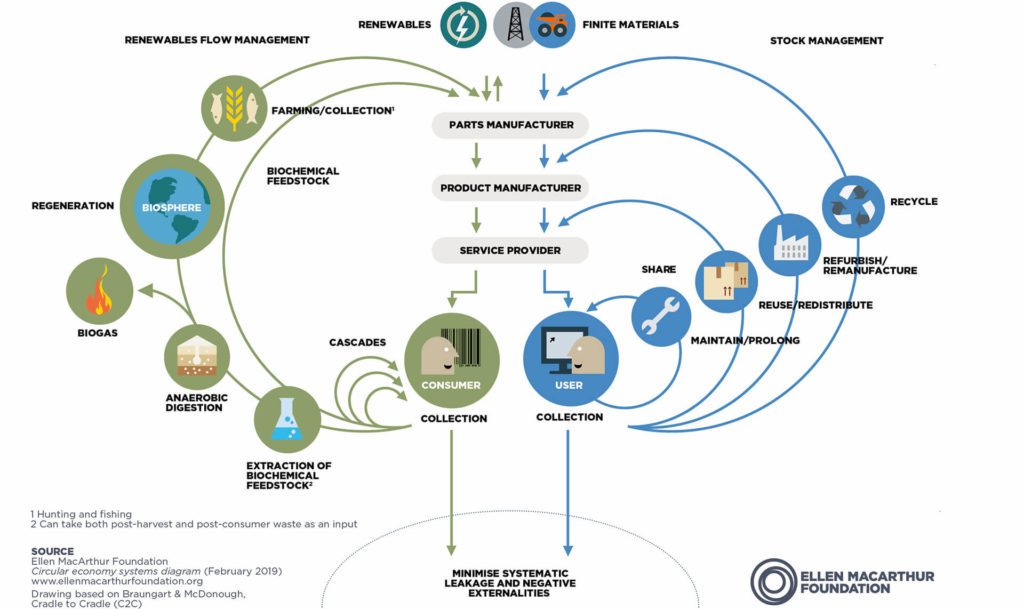

The circular economy is about enabling the circular flow of resources by adding, retaining and recapturing the value embedded within the resource. It’s the understanding that regenerative practices be centered on biomass management and the broader biocycle. It’s the recognition that one product could lead to another product, which could be reused or pulled apart and added to yet another product through a process called ‘cascading’.

Cascading and value recapturing provide opportunities for new partnerships and recovery efforts. Cascading includes the concepts of slowing, narrowing and closing material flow cycles to manage the speed at which resources move through the system. It offers off-ramps to phase some components and products out of circulation.

Cascading includes the concepts of slowing, narrowing and closing material flow cycles to manage the speed at which resources move through the system.

Contemporary materials management methods are not yielding the required carbon emissions reductions, public health improvements, or progress toward the Sustainable Development Goals (SDGs) set by the United Nations. We must accelerate emissions reductions on all fronts, and we must begin by scaling the technologies that will transform the built environment.

Investments in Research and Standardization

Extending the circular economy to all corners of the building and design sector will require the implementation of standards, an investment in research and efforts to scale technology.

The circular economy is an interdisciplinary tool requiring calibration and collaboration. Without standards, industries will attempt to address the problem in different ways. The international standards organization (ISO) is scheduled to release a circular economy standards package in early 2024, and UL will be releasing one in 2023. These standards are produced through an open multi-stakeholder calibration and provide concrete recommendations for shifting organizations towards the circular economy.

In the absence of an international standard, several reputable organizations, like the Cradle-to-Cradle Institute and the Ellen MacArthur Foundation, have offered guidance on how to define the circular economy. All have landed somewhere around the idea that a circular economy is one where the flow of resources is prioritized, alongside a desire to respect and protect the land and people.

Research and development activities typically take decades to safely scale for market adoption. The good news is that investment in the technologies needed in a circular economy exist today or are scaling now, with many more on the horizon, thanks to investments made 10-to-20 years ago. New solutions and innovative technologies will continue to emerge when collaborations and partnerships form through connections made through the circular value chain.

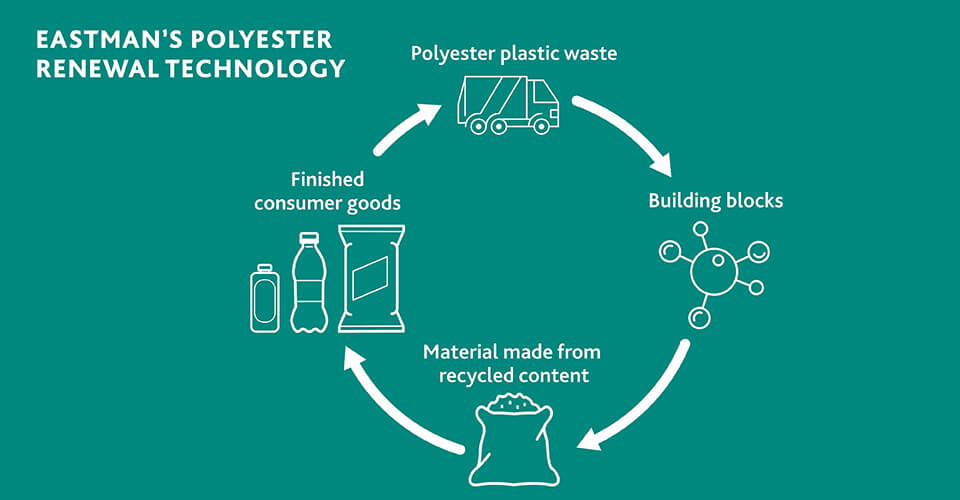

At Eastman, we’re excited by the opportunities presented by the circular economy to assist with the collection of materials previously deemed difficult to recover; materials like hard-to-recycle plastics, textiles and fibers. Eastman’s 2021 methanolysis plant in Kingsport, Tennessee, and the one planned for France, use a depolymerization technology to unzip the polymer used in plastic or textiles, and reconstitute it into new feedstocks, allowing for material-to-material recycling that keeps carbon in play and leaves fossil feedstocks in the ground.

Eastman is also seeking opportunities to turn previously non-compostable inputs into certified compostable inputs, which when added to a single-use solution, like a biodegradable straw, or a textile, brings the final product one step closer towards being fully certified compostable.

We invite you to learn more about what we’re doing at Eastman and explore how we can work together to accelerate the circular economy.