Treating Wastewater With Ceramic Filters

Introducing ceramic filters is more sustainable and more durable in the long-run for treating wastewater. The REMEB technology is being tested in Murcia, Spain, and can be deployed in any municipality that may need to update its wastewater treatment facilities.

REVOLVE interviewed the coordinator of the REMEB project, Elena Zuriaga Agustí, to learn more.

What is the innovative process behind the REMEB wastewater treatment process?

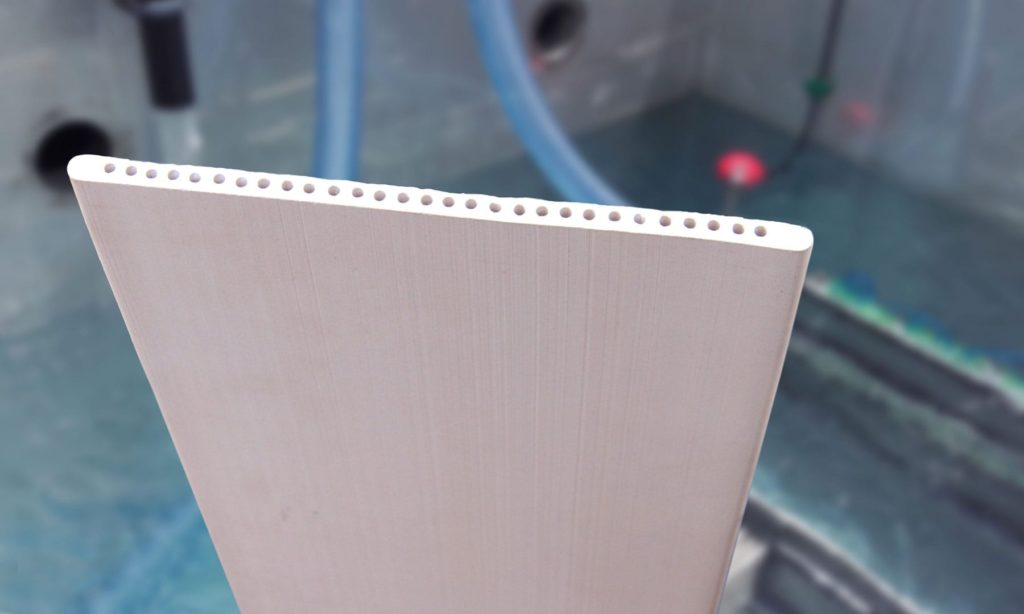

The REMEB project consists of a membrane bioreactor (MBR) that was developed to promote water reuse in a municipal Wastewater Treatment Plant (WWTP). In a given MBR, a biological reactor is combined with the membrane technology, where the membranes act as a barrier between the biomass and the water treated.

REMEB ceramic membranes are manufactured with low-cost materials in order to decrease the initial upfront and operational costs of the technology, as compared to MBRs with organic membranes and MBRs of conventional ceramic membranes.

The advantage of the ceramic membranes against the polymeric ones is that they have better mechanical, chemical and thermal resistance. In addition, they have longer durability and higher robustness.

How is your membrane filter technology unique?

The novelty of the REMEB ceramic membranes is that they are sustainable since they are manufactured with low-cost materials. They are made with wastes, in addition to the typical raw materials used in the ceramic tile industry. Instead of the commonly-used pure ceramic oxides (alumina, titania or zirconia), these are based on waste and by-products obtained in agricultural and industrial processes from olive stones, marble powder and chamotte from fired tile scrap.

How can it be applied to other industries?

During the REMEB project, the membranes have been validated in Aledo, a municipal WWTP, located in Murcia, Spain. The membranes were implemented in a MBR designed and built for the project, in a WWTP that already had an MBR, so both have been compared in the same conditions.

These membranes can also be used to treat industrial wastewaters. Since the membranes are ceramic, they can be used under extreme conditions (temperatures or pH-levels). The idea is to validate the REMEB MBR in an industrial WWTP.

How big is the market for such deployment?

The European Commission proposed on May 2018 new rules to stimulate and facilitate water reuse in the EU for agricultural irrigation. Approximately 2.4% of the treated urban wastewater effluents in Europe are reused, which is less than 0.5% of annual EU freshwater withdrawals. However, the EU potential is much higher, estimated in the order of 6 billion cubic meters – six times the current volume. Due to the EU’s intention to encourage the reuse of water, REMEB technology has great potential to be deployed.

What are the next steps for REMEB?

The next steps for the REMEB project is the improvement of the selective layer and optimizing its application through inkjet technology, which will allow to deposit layers according to the necessary requirements. This work will be funded through the Spanish Science, Innovation and Universities Ministry (RTC-2017-5897-5).