Recharged for a Circular Future

With the race for critical minerals intensifying, the question is no longer just how to build more batteries, but how to make the ones we already have go further.

The global shift to electric vehicles (EVs) is essential to decarbonising transport and forms a cornerstone of the European Union’s plan to reach carbon neutrality by 2050. As EV sales continue to increase, having reached 17 million worldwide in 2024, interest and questions about battery disposal and reuse have been top of mind for consumers, policymakers, and the automotive industry.

The stakes are high: EV batteries can contain more than 200 kg of critical minerals, such as lithium, nickel, and cobalt. As mineral mining is both exploitative and environmentally unsustainable, recycling existing raw materials offers a crucial path forward – one that could meet more than half of the lithium and nickel demand for lithium-ion batteries by 2040. Yet the vision of a circular battery economy is still far from reality. As a November 2024 Deloitte report makes clear, we simply don’t have enough end-of-life (EoL) batteries to feed the recycling market today. The first generation of mass-market EVs is only now nearing decommissioning, meaning recycling capacity will remain underutilised and mineral shortages will persist for years to come. In the meantime, how can these valuable resources be given a second life?

Three roads to an EV battery’s second life

When an EV battery can no longer power a car at peak performance, it doesn’t have to head straight for the scrapyard. There are three main roads to a second life: reusing it in another vehicle, repurposing it for a different application such as stationary energy storage, and recycling it to recover valuable minerals for new batteries. Each route has its trade-offs, but together they form the backbone of a circular battery economy.

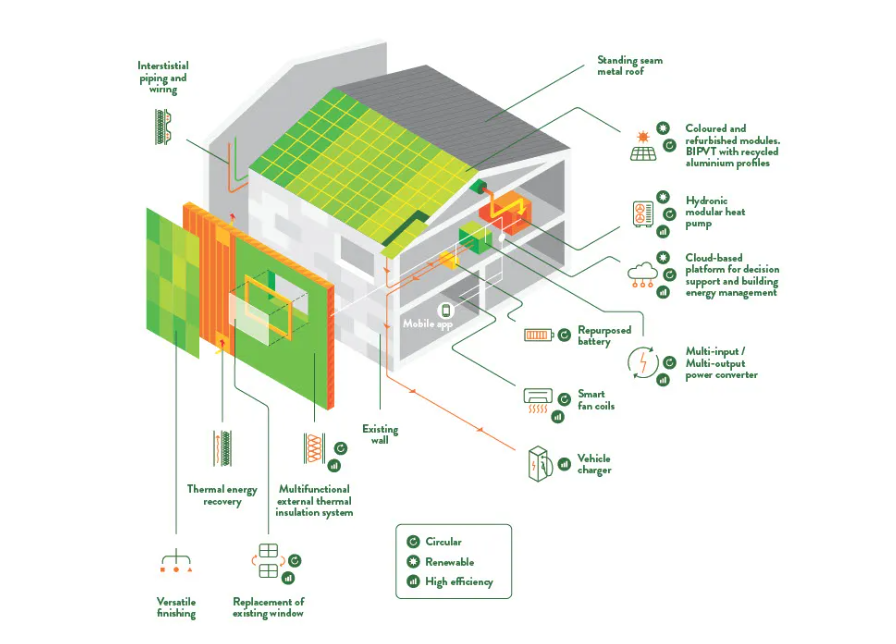

Repurposing, in particular, is gaining momentum. After 10 to 15 years, EV battery capacity drops below the threshold required for road use – typically around 70-80% of their original capacity, but batteries can still be viable for less demanding applications. One promising example comes from SolarTechno Europe, a partner in the EU-funded Horizon Europe project RE-SKIN, which aims to integrate repurposed batteries into building energy systems. Working with cells recovered from Mitsubishi Outlander plug-in hybrid vehicles, SolarTechno Europe is creating battery energy storage systems (BESS) for photovoltaic-powered heating and cooling. These second life systems balance energy loads, reduce reliance on the grid, and help cut building emissions.

After 10 to 15 years, EV battery capacity drops below the threshold required for road use – typically around 70-80% of their original capacity

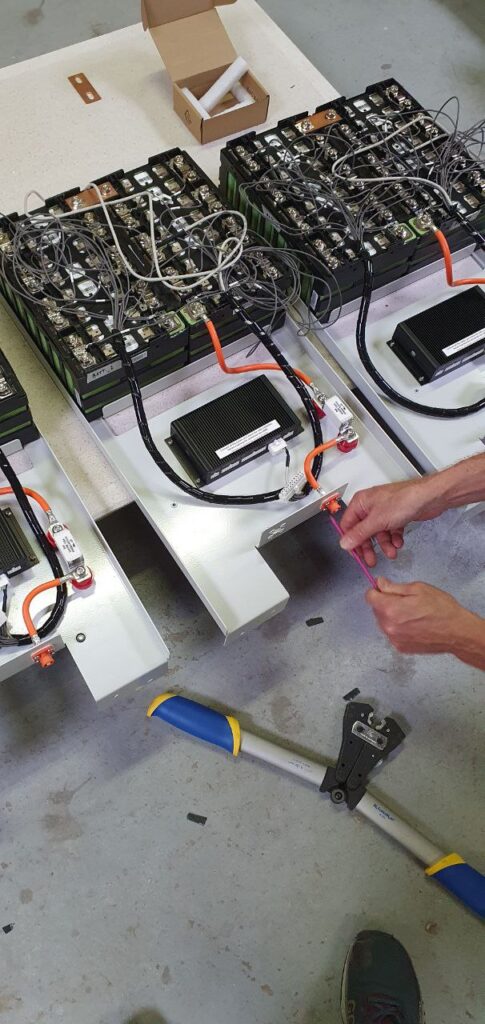

The repurposing process begins with safely removing the battery from a decommissioned vehicle, as even “spent” packs can hold significant energy. The pack is then tested to ensure it’s safe and viable before being opened and separated into smaller modules. “Once we’ve selected the healthy modules, we reassemble them into a new ‘second life’ battery system,” Aidan Heddes, Business Developer at SolarTechno Europe, tells REVOLVE. “We wire them together and integrate the necessary control electronics to ensure they perform reliably in their new application.” The final step is installing the “brain” of the battery, which, as Heddes explains, “monitors performance, manages charging and discharging, and safeguards the pack against any potential hazards.”

What are BESS and what role do they play?

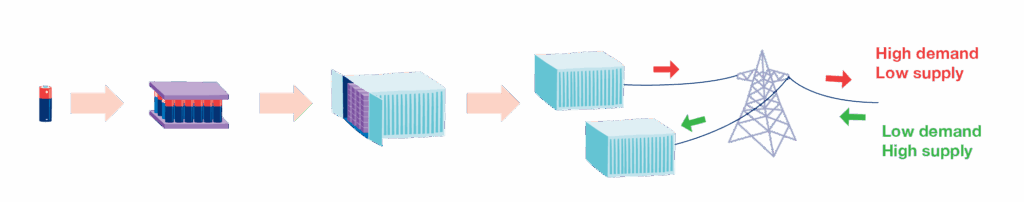

BESS are systems that store electrical energy using rechargeable batteries. These systems have the ability to release that energy when needed. They typically contain both hardware and software components and can perform several supportive functions to the electrical grid. This can include storing surplus electricity when supply exceeds demand and discharging stored energy when demand exceeds supply, helping balance the electrical grid by providing ancillary services that improve its reliability and efficiency.

A life cycle assessment conducted for the RE-SKIN project reveals that repurposing batteries delivers clear environmental benefits. Compared to new battery systems with the same effective capacity, repurposed systems reduce greenhouse gas emissions by 38% to 55% across most categories, including global warming potential, fossil resource use, and water consumption.

How does recycling stack up?

Recycling EV batteries is a complex and rapidly evolving process, with several competing techniques for extracting valuable raw materials. The three most common approaches: hydrometallurgical, pyrometallurgical, and direct recycling, differ in efficiency, cost, and environmental impact.

Hydrometallurgical recycling uses chemical leaching and solvent extraction to recover up to 99% of nickel, cobalt, and lithium, making it highly efficient and broadly applicable, particularly for high-value chemistries. Direct recycling, still in its early stages, aims to preserve and rejuvenate cathode materials without breaking them down into their elemental components. With the lowest environmental footprint of the three, it shows particular promise for lithium iron phosphate batteries and manufacturing scrap. Pyrometallurgical recycling, by contrast, relies on high-temperature smelting to recover nickel and cobalt but often loses lithium in the process. While it is well established, it is energy-intensive and carbon-heavy, hardly the blueprint for a future circular economy.

Yet even the most advanced recycling methods face significant hurdles. Pyrometallurgy, in particular, generates substantial emissions and often results in the permanent loss of lithium and manganese. Supply constraints add another layer of difficulty. With the first wave of mass-market EVs not reaching EoL until the 2030s, recycling facilities will struggle to run at full capacity before then. Infrastructure gaps, especially in collection systems and the uneven distribution of recycling plants, further limit what’s possible.

Safety is another constant concern. Damaged or degraded lithium-ion batteries can enter thermal runaway and catch fire during transport or dismantling. Without robust safety protocols, the process meant to enable a cleaner future risks carrying serious environmental and human costs. Overcoming these challenges will require more than technical breakthroughs — it will demand regulatory frameworks that set clear targets, standardised designs for recyclability, and the expansion of infrastructure needed to recover batteries at scale.

Setting the standard

Policy is beginning to reflect the urgency of building a more circular battery value chain. The EU’s new Battery Regulation, which entered into force in August 2023, sets mandatory targets for recycled content: 6% lithium and nickel, and 16% cobalt in batteries by 2031, rising to 12%, 15%, and 26% respectively by 2036. On 4 July 2025, the European Commission introduced detailed, harmonised rules for calculating and verifying both recycling efficiency and material recovery rates.

Still, when it comes to repurposing, regulatory frameworks remain thin. “There’s currently no specific regulation for repurposed EV batteries,” Heddes points out. “That makes it very difficult to insure buildings with these systems, something we’ve seen first-hand at our French demo site.” Without dedicated safety and technical standards, insurers remain wary, and developers face uncertainty over compliance.

Without dedicated safety and technical standards, insurers remain wary, and developers face uncertainty over compliance.

Aidan Heddes, Business Developer at SolarTechno Europe

Technical hurdles add to the challenge. Testing decommissioned battery cells, critical for ensuring safety, can be time-consuming and costly. “You don’t want potentially dangerous cells in a repurposed battery pack,” Heddes notes. Without standardised protocols for assessing and certifying second life cells, each project must navigate its own path, adding delays and costs.

Heddes believes the solution lies in separating regulatory treatment of new and repurposed batteries. “Clear safety and technical standards for repurposed cells would give insurers more confidence and make these projects far more viable,” he says. Without them, the widespread adoption of repurposed systems risks stalling.

Repurposing, while not a substitute for recycling, is a valuable addition to the process, stretching battery lifespans, creating interim value in sectors like construction and renewable energy, and buying time to scale up Europe’s recycling infrastructure. But to unlock its full potential, policy needs to evolve as quickly as the technology.

Clear safety and technical standards for repurposed cells would give insurers more confidence and make these projects far more viable.

Aidan Heddes, Business Developer at SolarTechno Europe

Circular goals require circular thinking

Europe’s climate ambitions hinge on electrifying its mobility and energy systems while keeping their environmental footprint in check. That means more than switching fuels; it means rethinking how materials are sourced, used, and reused.

Recycling will be indispensable, but for now it cannot do the job alone. Repurposing provides a practical bridge – one that delays extraction, cuts emissions, and squeezes more value from resources already in circulation. As the RE-SKIN project and similar initiatives show, the technology is ready. What’s needed now is systemic backing: targeted regulation, upfront investment, and product design that anticipates a second life from the outset.

In the race to close the loop, Europe must plan not just for the end of the road, but for the road after that – because in the circular economy, endings are only ever beginnings.